CHEMECH'S CREDENTIALS

Technical personnel at mineral processing plants are generally very busy managing their day-to-day tasks, and often don’t have time to fully identify, analyse and resolve plant optimisation and debottlenecking opportunities. They often turn to "design office engineers" who don’t have the right combination of operational and design experience required to deliver practical outcomes, sympathetic to operability and maintainability issues, and with easy-to-integrate and cost-effective solutions.

Unlike most consultants, Chemech maintain ongoing contact with operating personnel from our past projects to continuously build our operating and design database for future projects. It also allow us to stay abreast of the changes to the operating landscape, which evolves rapidly, particularly with regard to ever-tightening OHS&E requirements. When operational experience and knowledge is combined with considerable expertise in plant data analysis, Chemech can rapidly determine cost effective and practical plant optimisation and debottlenecking options.

Chemech’s involvement in a number of successful optimisation and debottlenecking projects means that we won't make the common mistakes we regularly see, such as:

Possessing a unique combination of operational experience and design success, Chemech has the right mix of skills and experience to practically and effectively debottleneck and optimise mineral processing plants.

OUR EXPERTISE

-

Performing analysis on incorrect, inappropriate, or improperly filtered operational data.

-

An obsession with modelling (e.g. comminution, leach/adsorption), often producing unrepresentative or unrealistic outcomes.

-

Solutions driven by an over-reliance on operating opinions, which often focus on treating symptoms rather than causes. Unconscious bias from past experiences often distorts the true situation.

-

Operability, maintainability and safety precautions are not sufficiently considered due to the lack of exposure to plant operations by design office engineers.

-

Debottlenecking and upgrade options can be unnecessarily constrained due to a lack of operating knowledge and benchmarking data.

-

The capacity of existing equipment can be understated based on historical “myths” and may not be adequately assessed as a result e.g. “the maximum speed has always been 75%”.

-

Upstream and downstream constraints are not suitably considered, and the bottleneck is just moved elsewhere.

-

The complexity of the brownfield environment is often understated when proposing simple and cost-effective solutions.

HOW WE CAN OPTIMISE & DEBOTTLENECK YOUR PROCESS PLANT

Metallurgical optimisation to increase recovery, improve product quality, or reduce costs (e.g. reagent usage reduction).

Preparation of documentation for debottlenecking and upgrade projects including scopes of work for engineering design, financial evaluations, and project justifications.

De-bottlenecking options analysis using plant and equipment data to identify bottlenecks and indentifying the engineering upgrade options required to alleviate them.

Equipment performance reviews to identify capacity or availability improvement opportunities.

Assistance within the owner’s team during the engineering design and execution of optimisation and debottlenecking projects.

OH&S and Environmental risk reduction projects.

Scoping and assisting with plant trials to ensure that the correct controls are in place and data collection requirements are clearly identified and managed.

SOME OPTIMISATION & DEBOTTLENECKING SUCCESS STORIES

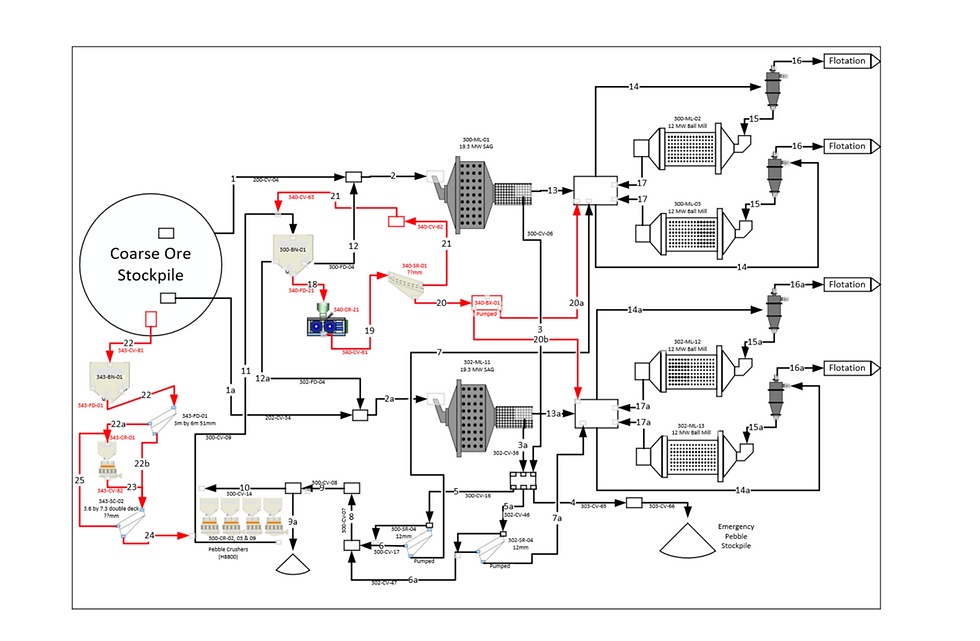

Following a 5 year ramp up period and several flowsheet modifications, plant throughput at Goldcorp’s Peñasquito operations was still well short of its 130,000 tpd nameplate in 2014 (109,000 tpd). The comminution flowsheet had become very complex (SABC with secondary crushing and a HPGR on crushed pebbles) and due also to some poor design features, the operations team had been unable to ramp up to design throughput. Goldcorp therefore engaged Chemech to provide an independent assessment of the process plant throughput capability and to propose options for optimisation and debottlenecking. Chemech developed complex models using plant data to identify the throughput bottlenecks and assess the impact of their proposed optimisation and debottlenecking options. Based on this analysis, Chemech proposed a low-capex optimisation program aimed at improving the control, operation, and availability of the major equipment to increase throughput to 90-95% of nameplate. The information gained during the optimisation phase could then be used to aid the selection of options to debottleneck the plant and further increase its capacity to 100-105% of nameplate. Chemech then provided high-level expansion options to increase throughput beyond 115% of design throughput.

Newmont’s Boddington Gold Operation achieved commercial production in 2009 and has since produced over 10Moz of gold (by 2025). Chemech played an integral role in the Boddington design and the strong relationships developed during this period resulted in a partnership that subsequently resulted in the completion of many successful optimisation and debottlenecking projects. During two major debottlenecking studies, Chemech extensively analysed plant data and used dynamic modelling to identify a number of relatively minor upgrades capable of increasing throughput beyond 38.6Mt/a (110% of design). These included conveyor capacity upgrades, HGPR speed/pressure increases, fine screen aperture reductions, ball mill power draw increases and increased hydraulic flow capacity through the flotation, leach/adsorption and tailings disposal circuits. Chemech assisted with progressive implementation of these projects, and throughput exceeded design by 15% in 2018 (40Mt/a).

Chemech’s involvement in optimisation and debottlenecking projects at Boddington was instrumental in identifying, analysing and recommending low-capital-cost and easy-to-implement upgrades that effectively unlocked significant throughput and recovery increases. The success of these projects has benefited greatly from Chemech's intimate knowledge of the process plant design, excellent data analysis, practical engineering competency and a real skill for stakeholder engagement. Chemech have been a significant part of Boddington's success from the early studies through to the present day.

- Steve Hart, Newmont's Processing Manager – Boddington Gold Project¹

1: This statement reflects the personal views of Steve Hart and does not constitute an official endorsement by Newmont Corporation.